Vandersanden-Together to Zero

Vandersanden is not only one of the largest, but also one of the most sustainable family-owned brick producers in Europe. At our nine factories in Belgium, the Netherlands and Germany, we produce facing bricks, pavers and brick slips. We also provide our customers with innovative facade and street solutions. Craftsmanship, co-creation, innovation and sustainability are the keywords of our approach. And our ambitions are high: we aim to be completely CO2-neutral by the year 2050.

To achieve that goal, we make targeted investments in order to render our processes, production methods and factories more sustainable. But that’s not all. By developing new, innovative products, we contribute to reducing raw material usage, energy consumption and CO2 emissions. This is preferably done together with our partners. After all, our motto is ‘Together we build greatness’. With the ‘Together to Zero’ programme, we are inviting our customers, suppliers and partners to join us on our journey towards a completely CO2-neutral footprint.

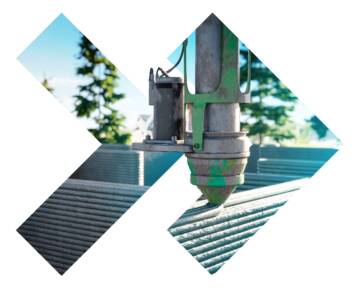

Together to Zero comprises eight focus areas. Our family-run company uses smart automation to promote more efficient building methods that are aligned with the (future) labour shortage, while at the same time resulting in significantly reduced usage of raw materials and energy. Smart automation has the added advantage of lower costs, fewer errors, and better quality. A good example is RoboBrick®, a total facade solution for the automated processing of brick slips with an impressive 60% fewer raw materials and energy. Since 3 1/2 times more brick slips can be transported compared to bricks, the environmental impact of the transport is also much lower.

Dematerialisation is our second focus area. For 90 years, we have been firing bricks in the customary thickness of 10 centimetres. But why exactly? There are no technical reasons to maintain this traditional size. But the energy crisis and our sustainability vision offer sufficient grounds to use fewer raw materials and less energy. That is why we have narrowed traditionally fired bricks from 10 to 7 centimetres. It goes without saying that the narrow bricks perfectly measure up to the traditional bricks in terms of quality and appearance. A few added advantages: more bricks fit inside a truck and there is more room for insulation, which in turn steps up the sustainability factor. Apart from facing bricks, we also produce narrower pavers made from river clay, a renewable raw material. This year, we are taking extra steps to convince the market that this narrow brick range – the S line – offers comparable quality and construction possibilities, while at the same time being a much more sustainable option.

Water management means that we are economical with our water usage. We use as little water as possible, reuse water where feasible and offer climate-adaptive solutions for public spaces. Drainflow®, for instance, is a water-permeable paver that helps to infiltrate rainwater into the soil during heavy downpours. This prevents flooding and helps to establish a groundwater reserve to better manage long-term droughts. In the circular materials focus area, we make every effort to limit waste to a minimum, such as by using sustainable packaging methods and reusing materials. We also offer a free return service for disposable pallets.

We want to contribute to solutions for the social challenges that lie ahead – not because we are required to by law, but because it is the right thing to do.

Vandersanden aims to achieve mobility without fossil fuels. We are gradually making the switch to a fully electric vehicle fleet. This means that every new vehicle we order is electric. We charge them using 100% green electricity, whether at home, at work or at public charging stations. Apart from innovative products with as low an environmental impact as possible, we aim to ensure that our production locations use as little energy and generate as few emissions as possible. Our new kiln in Tolkamer emits 25% less CO2, making it the most eco-friendly kiln in Europe. We also invest in renewable energy sources, such as solar panels and cogeneration plants. We installed our very first wind turbine at our production site in Lanklaar in the spring of 2022.

In the focus area of CO₂-negative products, we have introduced our newest and most pioneering invention: the carbonated brick, a CO2-negative brick. This carbonated brick offers the best of both worlds. We reduce the use of raw materials by 80% by using residues from the steel industry – carbinox and stinox sand – and combining them with fine sand. We no longer emit CO2, but capture it! In other words, the bricks are not hardened in kilns, but by adding CO₂. Fossil fuels are no longer needed for the kilns because solar panels and a wind turbine provide the necessary energy. In Lanklaar, Belgium, the first factory is currently under construction. In the meantime, we are engaged in dialogue with companies that emit large amounts of CO₂ to determine whether we can build a similar factory in their area to capture CO₂ on site.

At Vandersanden, we do not think in terms of years, but generations. Sustainable entrepreneurship is part of our very DNA. We want to contribute to solutions for the social challenges that lie ahead – not because we are required to by law, but because it is the right thing to do. We believe that doing good for society and the environment pays off in the long term. That is our commitment as a company. As an industry, as a company and as a society, we have to join forces to allow good ideas and bold investments to flourish. We invite everyone to join us on our journey.

Together we build greatness

Together to Zero!

How do we do this?

Discover more on Together to Zero

Latest insights & stories

A Global Movement: The World Unites in a Pink Pledge for Clean and Sustainable Water

5,000 participants. 32 countries. €30,000 funds raised. And that's just the beginning.

Picture this: One step that sends ripples across the globe, transforming lives and creating waves of change. You might wonder, how can such a simple action for most of us have such a profound impact?

Sustainability and circularity in construction

Join us in transforming the future of construction, creating buildings that not only stand the test of time but also contribute to a healthier planet!

RainTunes: Shower scenarios for the soul

Light, hearing, smell, and touch: Together with experts, we have developed sensuous scenarios that turn showering into an individual experience. Whether you want to prepare for the day ahead or relax after working out. Whether you want to refresh after a day’s work or unwind at the end of the evening: RainTunes surprises with multisensory experiences.*

*Currently available only in Germany and Austria.