Recticel launches the RE-engineered IP PIR insulation

Recticel is committed to high-performance insulation solutions that continuously reduce its carbon footprint, without compromising on the most stringent technical requirements.

By removing aluminium from the composition of RE-engineered IP PIR board, the carbon footprint of the facing is significantly reduced, by up to 40%.

The elimination of the aluminium component from the IP PIR board also reduces the risk of corrosion. This innovation contributes to a more durable product and ensures long-term performance and optimal insulation efficiency.

Those who apply RE-engineered IP PIR insulation in projects make a direct contribution to sustainability goals. You not only reduce your carbon footprint, but also choose a product that combines advanced innovations with proven performance.

Latest insights & stories

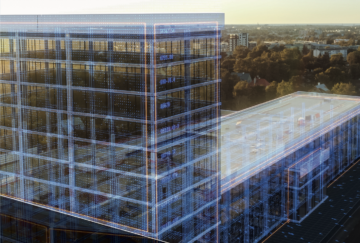

BIM and digital twin for road safety and sustainability

The Department of Mobility and Public Works aims to make our mobility system more efficient by means of methodical digital solutions. They therefore are implementing BIM, a virtual way to build and collaborate on our infrastructure. Their goal? Setting up a ‘digital twin’: digital equivalents of our infrastructure and artworks. With these solutions they will be able to create analytics for optimal management via machine learning and smart data collection. To achieve that goal, collaboration is crucial.

MOBILIDATA

In Flanders, we strive to work on tomorrow’s mobility today. That includes the Mobilidata programme. With this programme, various levels of government, companies and researchers are jointly developing innovative, technological traffic solutions for road users, such as better route advice, tailored traffic notifications and intelligent traffic lights. New connected mobility and know-how do not stop at our national borders however, so international collaboration is needed to exchange knowledge and set up joint projects to implement it.

Digital sovereignty guarantees data security in the public cloud

When companies consider migrating to the public cloud, they are sometimes held back by security risks and compliance and governance constraints. Thus the interest in digital sovereignty, Gwénaëlle Hervé, Public & Sovereign Cloud Lead at Proximus NXT, explains.